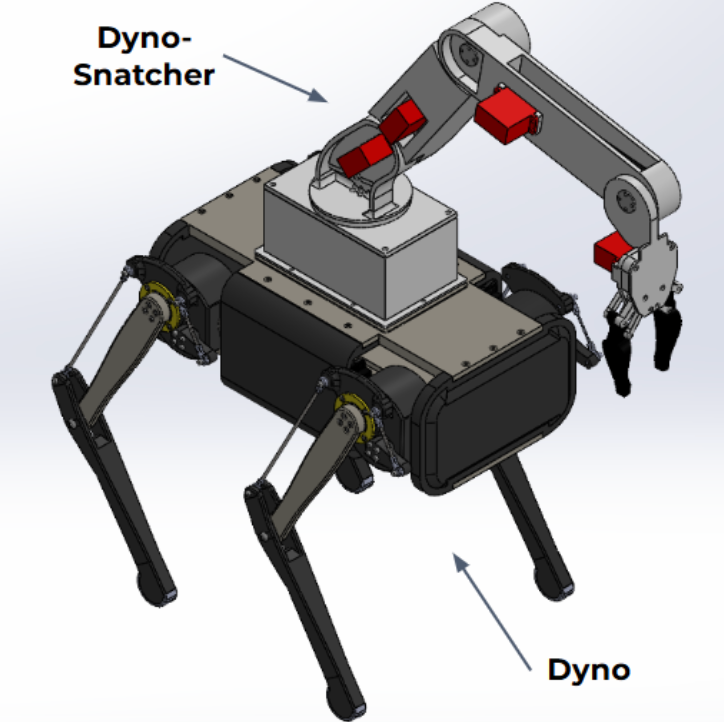

Search and rescue operations require precise, durable, and adaptable robotic solutions to handle hazardous objects in complex environments. Current technologies often fall short in reliability and control accuracy, limiting their effectiveness. This project aims to develop a robotic claw that interfaces our the quadruped rescue robot, Dyno, enhancing its precision, durability, and real-time feedback capabilities to improve rescue mission safety and efficiency.

The Dyno-Snatcher is a robotic claw designed to assist search and rescue teams by remotely removing debris and obstacles in hazardous environments using a quadruped robot. The key objectives include:

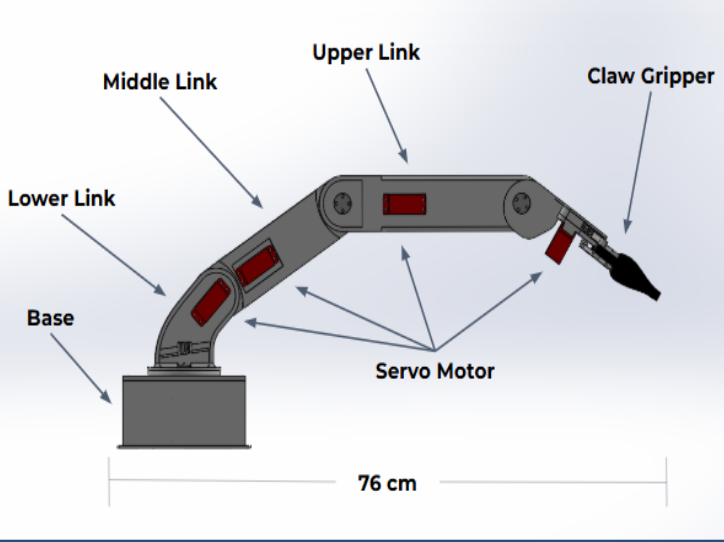

Develop a 4 DOF arm that is lightweight (<8 lbs) and portable

Claw must lift at least 2 lbs and grasp and object up to 3 inches in diameter

Validate structural integrity through stress analysis and load testing

Test remote controlled operation for precise object manipulation (up to +/- 6.35 mm)

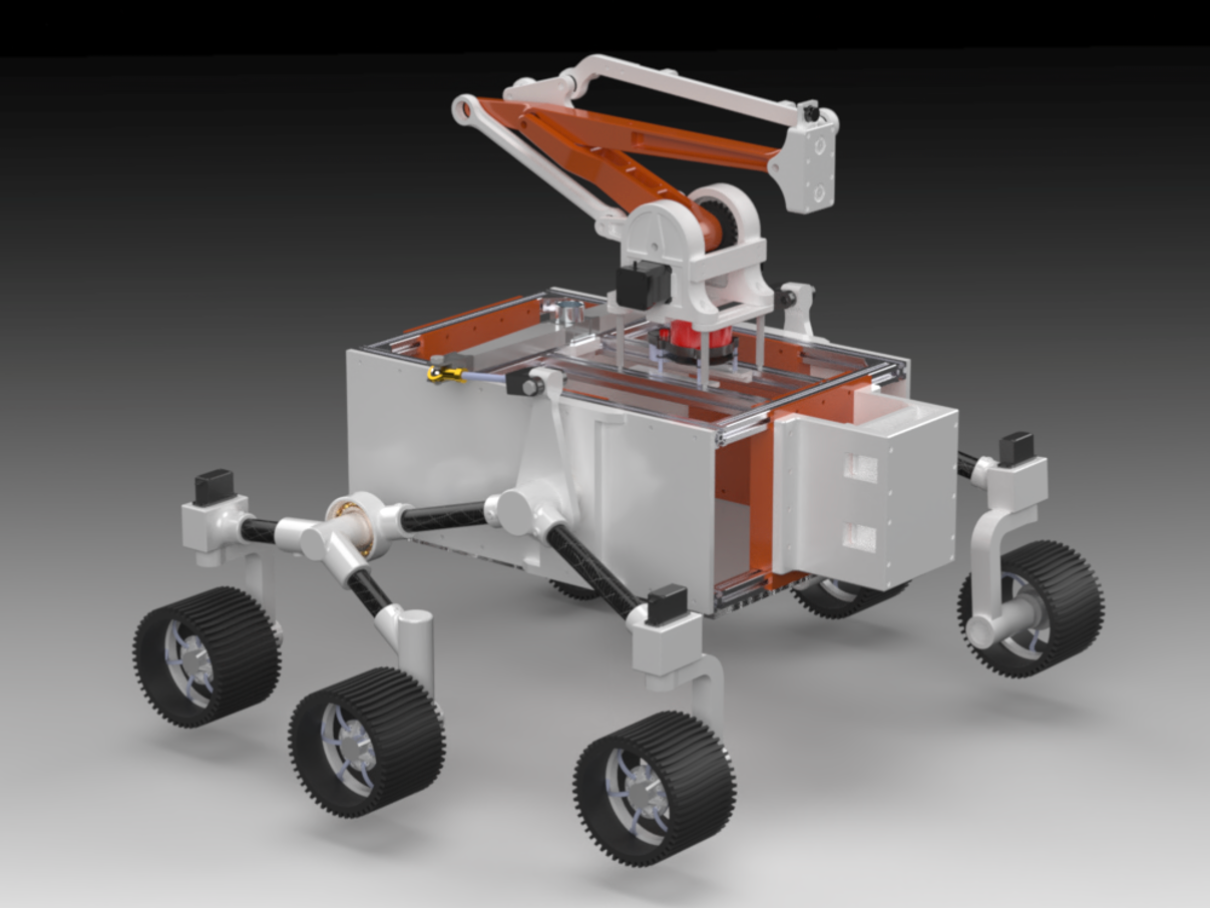

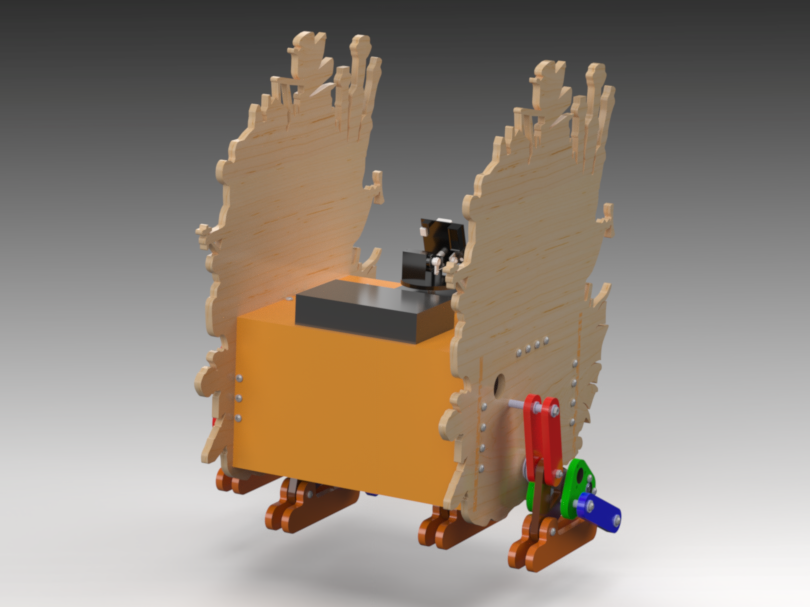

Full CAD Assembly of Dyno and Dyno-Snatcher

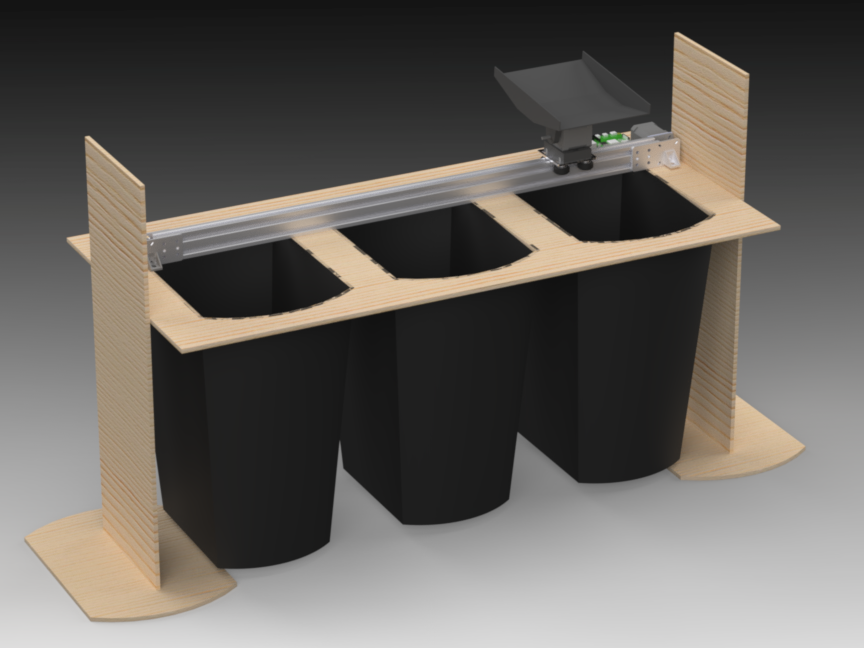

CAD of Dyno-Snatcher

Finite Element Analysis (FEA) Summary

Setup: The part was fully constrained at the servo horn mounting point and subjected to a 3 lbf load in the negative y-direction.

Results:

Maximum Stress: 3.909 MPa, well below PLA’s 60 MPa yield strength.

Maximum Displacement: 0.222 mm.

These results confirm that the design can safely accommodate the applied load with minimal deformation.

FEA SImulation on claw assembly 100% PLA infill

A black box diagram illustrating the inputs, subsystems, and outputs for a robotic system

My primary responsibility is designing and integrating a 4-DOF modular arm on the quadruped robot, enabling precise manipulation and lifting of hazardous objects.

We are currently in the manufacturing and prototyping phase, aiming to complete by early December 2024, with full integration of the robotic arm and quadruped targeted for the end of February 2025. See below for our timeline and milestones for this project.

Requirements

A requirements list for a robotic claw integrated with our Dyno quadruped rescue robot, outlining key functionalities such as handling objects up to 2 lbs, 4-DOF movement, and remote control operation. It emphasizes usability, real-time feedback, efficient power management, and adaptability to harsh environments, ensuring the system is lightweight, portable, and cost-effective for search-and-rescue missions.

Quarter 1: Research, Design, and Prototyping

Week 2: Initial Research & Concept Development

Research existing designs, identify areas for improvement, and brainstorm components.

Milestone: Preliminary design concepts completed.

Research existing designs, identify areas for improvement, and brainstorm components.

Milestone: Preliminary design concepts completed.

Week 3-4: Requirement Definition & Preliminary Design

Define project requirements (grip force, range, materials) and create early sketches.

Milestone: Requirements finalized, preliminary design drafted.

Define project requirements (grip force, range, materials) and create early sketches.

Milestone: Requirements finalized, preliminary design drafted.

Week 4-5: Technical Research & Component Selection

Research and select motors, sensors, and control boards; refine design for feasibility.

Milestone: Components selected, design refined.

Research and select motors, sensors, and control boards; refine design for feasibility.

Milestone: Components selected, design refined.

Week 5: Design Review & Validation

Review design to align with goals, validate components, and finalize the approach.

Milestone: Design review completed, ready for CAD modeling.

Review design to align with goals, validate components, and finalize the approach.

Milestone: Design review completed, ready for CAD modeling.

Week 6: Detailed CAD Modeling

Create a 3D CAD model, simulate movements, and adjust as needed.

Milestone: CAD model finalized, ready for prototyping.

Create a 3D CAD model, simulate movements, and adjust as needed.

Milestone: CAD model finalized, ready for prototyping.

Week 7: BOM & Assembly Start

Finalize BOM, order parts, and start assembling the structure.

Milestone: Components ordered, initial assembly started.

Finalize BOM, order parts, and start assembling the structure.

Milestone: Components ordered, initial assembly started.

Week 8: Mechanical Completion & Motor Integration

Finish assembly, mount motors, and wire control circuits.

Milestone: Mechanical structure and motors integrated.

Finish assembly, mount motors, and wire control circuits.

Milestone: Mechanical structure and motors integrated.

Quarter 2: Integration, Testing, and Optimization

Week 1-2: Software Development & Initial Testing

Write control algorithms, implement sensor feedback, and test basic functions.

Milestone: Basic software functional.

Write control algorithms, implement sensor feedback, and test basic functions.

Milestone: Basic software functional.

Week 3-4: Calibration & Performance Testing

Fine-tune controls and test grip with various objects.

Milestone: System calibrated and optimized.

Fine-tune controls and test grip with various objects.

Milestone: System calibrated and optimized.

Week 5-6: Integration with Humanoid Robot

Mount the claw, integrate with the main controller, and test interaction.

Milestone: Claw operational with humanoid robot.

Mount the claw, integrate with the main controller, and test interaction.

Milestone: Claw operational with humanoid robot.

Week 7-8: Advanced Development & System Testing

Implement advanced control patterns and test in dynamic environments.

Milestone: Advanced software integrated and tested.

Implement advanced control patterns and test in dynamic environments.

Milestone: Advanced software integrated and tested.

Week 9-10: Optimization & Documentation

Optimize all systems, conduct final tests, and prepare reports and videos.

Milestone: Project complete, ready for presentation.

Optimize all systems, conduct final tests, and prepare reports and videos.

Milestone: Project complete, ready for presentation.